What Are the Key Specifications and Components of Forklift Batteries?

Forklift batteries consist of multiple cells, typically lead-acid or lithium-ion, each producing around 2 volts. Key components include positive and negative lead plates, separators, battery terminals, electrolyte solution, intercell connectors, and the battery case or tray. Important specifications include voltage, capacity (amp-hours), dimensions, weight, and cycle life, all crucial for matching forklift requirements and optimizing performance.

What Are the Main Components Inside a Forklift Battery?

A forklift battery is composed of several integral parts: positive plates coated with lead dioxide, negative lead plates, separators that prevent short circuits while allowing ionic flow, battery terminals enabling electrical connection, electrolyte fluid (a mix of water and sulfuric acid in lead-acid batteries), intercell connectors joining individual cells, and a durable battery case that houses all components securely.

How Do Forklift Battery Cells Work and What Are Their Specifications?

Each battery cell stores and releases energy through chemical reactions between the positive and negative plates submerged in electrolyte. Standard forklift batteries contain a series of 2-volt cells connected to reach the required voltage (e.g., 24V, 36V, 48V). The capacity is rated in amp-hours (Ah), indicating energy storage ability, while cycle life measures how many charge-discharge cycles the battery can endure before performance degrades.

Which Specifications Are Critical for Selecting the Right Forklift Battery?

Voltage and capacity are primary technical specifications; forklifts usually require 24V, 36V, or 48V systems, with capacity ranging broadly (e.g., 100Ah to 1000Ah) depending on application. Battery size and weight must fit the forklift’s battery compartment and lifting mechanisms. Cycle life, charge time, and maintenance needs also influence selection, balancing performance and operational cost.

How Do Lithium-Ion Forklift Battery Components Differ from Lead-Acid?

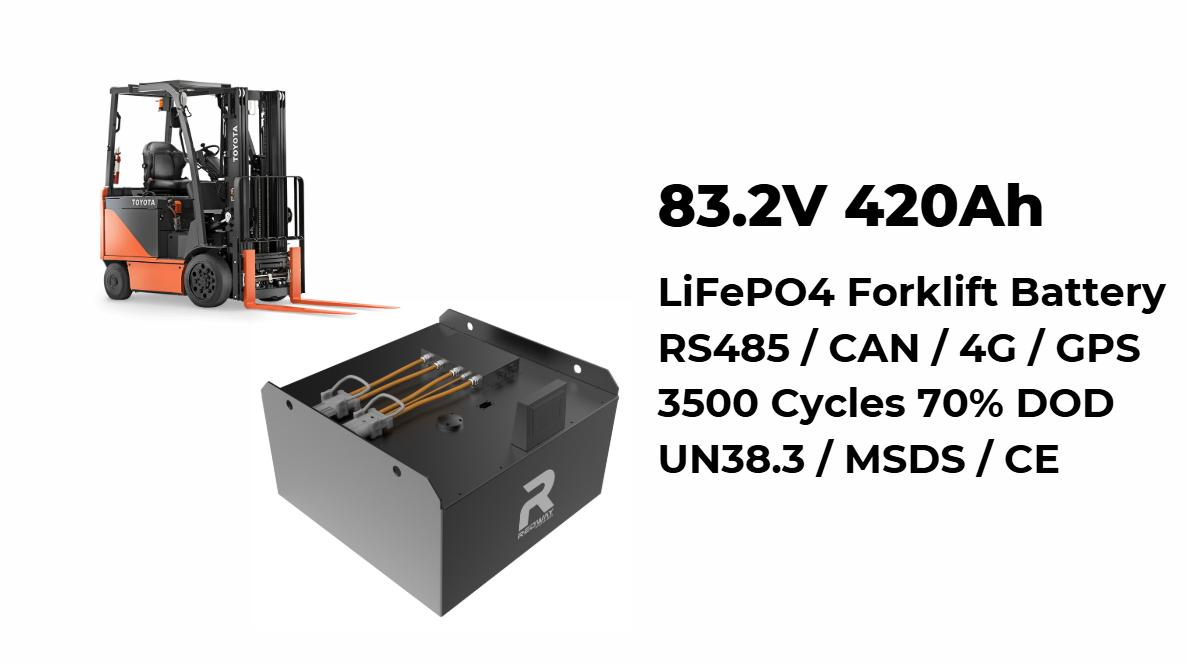

Lithium-ion batteries have components including cathodes, anodes, electrolyte (often lithium salt in organic solvents), separators, and current collectors. Unlike lead-acid batteries, they are sealed, maintenance-free, and made for faster charging and longer lifecycle. The chemistry (commonly lithium iron phosphate) optimizes safety, energy density, and charge efficiency.

What Is the Role of Separators and Electrolytes in Forklift Batteries?

Separators keep the positive and negative plates from direct contact, avoiding short circuits while allowing ionic flow during charging and discharging. Electrolytes—liquid sulfuric acid solutions in lead-acid batteries or lithium-ion-based electrolytes—enable ion transport, facilitating the electrochemical reactions that generate electric current.

How Important Are Battery Connectors and Harnesses in Performance?

Connectors and harnesses link individual cells and the battery to the forklift and charger, ensuring stable and efficient current flow. Quality connectors reduce resistance, improve safety, and ease maintenance. Modern molded connectors integrate cables and terminals for durability and ease of replacement.

What Physical Characteristics Define Forklift Battery Design?

Battery tray or tank provides structural integrity and protection against mechanical damage and acid spills. Packing materials stabilize cells inside the case, limiting vibration and shock damage. Vent caps and covers allow gas release during charging while protecting cells. Weight distribution affects forklift handling and must be considered during battery selection.

How Do Forklift Battery Size and Configuration Impact Usage?

Batteries are sized and configured by the number of cells and their arrangement (series or parallel) to meet voltage and capacity needs. Series connections increase voltage; parallel connections enhance amp-hour capacity. Proper size and configuration optimize runtime, charging frequency, and compatibility.

What Safety Features Are Included in Forklift Batteries?

Safety measures include flame retardant materials, spark-proof connectors, vents to release hydrogen gas safely, insulation, and robust casing to prevent acid leaks. Lithium-ion batteries incorporate advanced battery management systems to prevent overcharge, overheating, and short circuits.

Forklift Battery Components Overview Chart

| Component | Function | Importance |

|---|---|---|

| Positive & Negative Plates | Conduct electrochemical reactions | Core energy storage mechanism |

| Separators | Prevent short circuit, allow ion flow | Battery safety and function |

| Electrolyte | Medium for ion exchange | Enables chemical reactions |

| Battery Terminals | Connect battery to forklift and charger | Electrical conductivity |

| Intercell Connectors | Link cells in series or parallel | Controls battery voltage and capacity |

| Battery Tray/Case | Houses and protects cells | Durability and safety |

| Battery Connectors & Harness | Secure current flow and connections | Operational reliability |

HeatedBattery Expert Views

“The key to selecting and maintaining forklift batteries lies in understanding their detailed specifications and components,” says a HeatedBattery expert. “Knowledge of cells, separators, electrolyte chemistry, and connector technology is vital for ensuring safety, efficiency, and longevity. With evolving lithium-ion advancements, tailoring batteries to specific forklift usage and environment maximizes performance and operational savings. At HeatedBattery, we focus on delivering top-tier energy solutions that meet these rigorous demands for modern industrial fleets.”

Conclusion

Forklift batteries are complex, meticulously designed systems composed of multiple cells and components that work synergistically to deliver reliable power. Recognizing key specifications like voltage, capacity, and size alongside understanding internal components—plates, separators, electrolyte, connectors—enables informed battery selection and maintenance. Advancements in lithium-ion technology are reshaping the component landscape. Properly matching batteries to forklift requirements optimizes operational efficiency and safety.

FAQ

What are the principal components inside a forklift battery?

They include positive and negative lead plates, separators, electrolyte, battery terminals, intercell connectors, and the battery case.

How many volts does each forklift battery cell produce?

Each cell typically produces approximately 2 volts, connected in series for desired voltage.

What key specifications determine forklift battery suitability?

Voltage, capacity (amp-hours), size, weight, cycle life, and maintenance needs.

How do lithium-ion forklift batteries differ in components?

They have cathodes, anodes, lithium-based electrolytes, separators, and integrated management systems.

Why are battery connectors and harnesses important?

They ensure safe, efficient power transfer and simplify maintenance and replacement.