What Are the Different Types of Forklift Battery Technologies?

When considering forklift battery technologies, options like lithium batteries for forklifts, lead acid battery for forklift, and absorbed glass mat (AGM) batteries offer distinct advantages and challenges. Understanding these types can help you select the best battery for your operational needs.

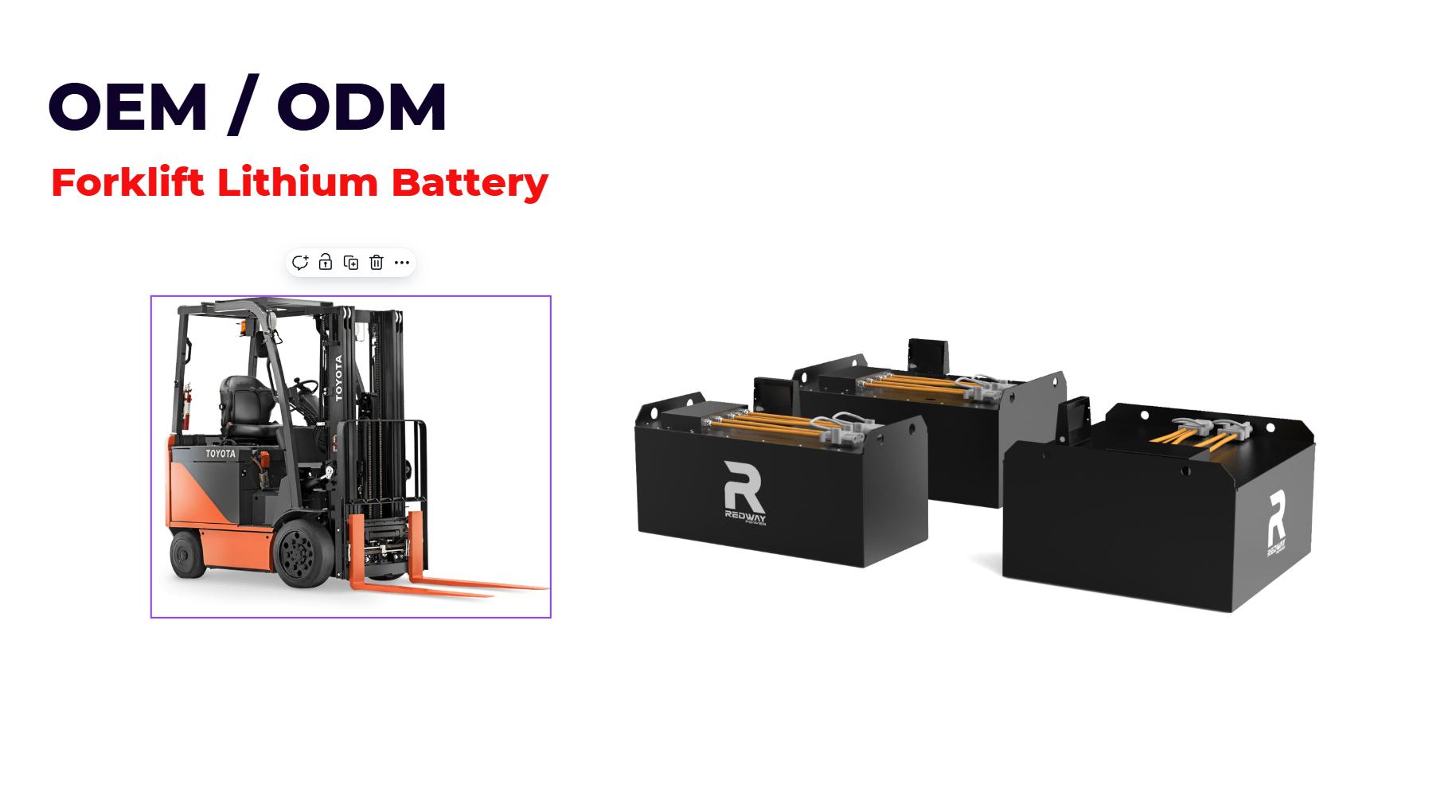

What Are the Key Features of Lithium Batteries for Forklifts?

Lithium batteries for forklifts offer high energy density, enabling longer run times and reduced weight. They feature fast charging capabilities, often allowing opportunity charging during breaks. These batteries are virtually maintenance-free, equipped with an intelligent battery management system for safety, and have a longer lifespan compared to traditional batteries, making them ideal for industrial applications. Lithium batteries for forklifts are increasingly popular due to their numerous benefits:

- Maintenance-Free: Unlike lead-acid batteries, lithium batteries do not require watering or regular maintenance.

- Fast Charging: These batteries can be charged quickly, often within one to two hours, allowing for more operational uptime.

Chart: Key Specifications of Lithium Batteries

| Feature | Specification |

|---|---|

| Voltage | 24V, 36V, 48V |

| Lifespan | Up to 10 years |

| Weight | Lighter than lead-acid |

| Charging Time | 1-2 hours |

| Maintenance | None |

How Do Lead Acid Batteries for Forklifts Compare to Other Types?

Lead acid batteries are cost-effective and widely used but require regular maintenance, including watering and equalizing charges. In contrast, lithium batteries offer faster charging, longer life cycles, and reduced downtime due to their ability to be charged opportunistically. AGM batteries provide faster charging and are maintenance-free but generally have lower energy efficiency than lithium options. Lead acid batteries remain the most common choice in the forklift market, known for their reliability:

- Cost-Effective: They are generally cheaper upfront compared to lithium options.

- Proven Technology: This technology has been used for decades, providing a familiar solution for many operators.

However, they require regular maintenance and have a shorter lifespan compared to lithium batteries.Chart: Comparison of Lead Acid and Lithium Batteries

| Feature | Lead Acid | Lithium |

|---|---|---|

| Initial Cost | Lower | Higher |

| Lifespan | 3-5 years | Up to 10 years |

| Maintenance | Regular watering needed | No maintenance required |

| Charging Time | 8 hours or more | 1-2 hours |

What Is a Traction Battery for Forklifts and Its Benefits?

A traction battery is designed specifically for powering electric forklifts and other material handling equipment. Its benefits include high discharge rates, durability under heavy loads, and the ability to withstand deep cycling. This makes traction batteries ideal for demanding applications, enhancing productivity and reducing operational costs in industrial settings. Key benefits include:

- High Capacity: These batteries are built to deliver sustained power over long periods, essential for heavy-duty applications.

- Durability: Traction batteries are designed to withstand deep discharges and frequent cycling.

Chart: Specifications of Traction Batteries

| Feature | Specification |

|---|---|

| Voltage Options | Typically 24V, 36V, or 48V |

| Amp-Hour Ratings | Ranges from 200Ah to over 800Ah |

| Maintenance | Requires regular checks |

Where Are Industrial Batteries for Forklifts Used Most Effectively?

Industrial batteries for forklifts are most effective in warehouses, distribution centers, and manufacturing facilities where material handling is critical. They support operations that require frequent lifting and transporting of goods, providing reliable power for extended shifts while minimizing downtime due to their efficient charging capabilities. Industrial batteries are utilized in various settings where forklifts operate, including:

- Warehouses: For material handling and inventory management.

- Manufacturing Plants: To move heavy materials and components efficiently.

- Distribution Centers: For quick loading and unloading operations.

These environments benefit from the reliability and performance of industrial batteries.

Why Choose Absorbed Glass Mat (AGM) Batteries for Your Forklift?

AGM batteries are a great choice due to their maintenance-free design, which eliminates the need for watering. They charge faster than traditional lead-acid batteries, have superior vibration resistance, and are leak-proof. AGM batteries also provide consistent power delivery, making them suitable for various industrial applications with moderate energy demands. Absorbed Glass Mat (AGM) batteries offer unique advantages:

- Maintenance-Free Operation: AGM batteries do not require watering, making them ideal for operations with limited maintenance capabilities.

- Safety Features: They reduce the risk of spills and leaks due to their design.

However, AGM batteries can be more expensive than traditional lead-acid options.Chart: Advantages of AGM Batteries

| Feature | Specification |

|---|---|

| Maintenance | None |

| Risk of Spillage | Minimal |

| Lifespan | Longer than lead-acid |

How Can You Maintain Different Types of Forklift Batteries?

To maintain forklift batteries, regularly check fluid levels in lead-acid types, keep terminals clean, and ensure proper charging practices. For lithium batteries, monitor temperature and charge cycles without needing water or equalization. AGM batteries require minimal maintenance but should be kept clean and dry to ensure optimal performance. Proper maintenance is crucial regardless of battery type:

- Lithium Batteries: Ensure charging practices are followed; avoid extreme temperatures.

- Lead Acid Batteries: Regularly check electrolyte levels and clean terminals.

- AGM Batteries: Keep terminals clean; no need for watering but check connections regularly.

Frequently Asked Questions

- How often should I replace my forklift battery?

Typically every three to five years for lead-acid; lithium can last up to ten years with proper care. - Can I use a lithium battery in place of a lead-acid battery?

Yes, but ensure your forklift is compatible with lithium technology. - What is the best type of battery for heavy-duty applications?

Lithium-ion batteries are recommended due to their efficiency and longer lifespan.