What Are the Best Battery Swapping Solutions for Forklifts?

Battery swapping solutions have emerged as a game-changer in the management of forklift operations, allowing for quick and efficient battery exchanges that minimize downtime. This article explores the mechanics of battery swapping, its benefits, and the equipment involved, including pogo stands and fast charging options.

What is battery swapping and how does it work for forklifts?

Battery swapping is a process where a depleted forklift battery is quickly replaced with a fully charged one. Operators drive the forklift to a designated battery exchange station, remove the old battery using specialized equipment, and install a new one. This method eliminates long charging times, allowing for continuous operation.

| Process Steps | Description |

|---|---|

| Battery Removal | The depleted battery is removed from the forklift. |

| Battery Replacement | A fully charged battery is inserted into the forklift. |

| Charging | The removed battery is connected to a charger while not in use. |

What are the benefits of using battery swapping solutions?

Battery swapping solutions offer increased productivity by minimizing downtime, as forklifts can operate continuously without waiting for batteries to charge. They enhance safety by reducing handling risks and optimize workflow by ensuring that fully charged batteries are always available for use. Battery swapping solutions provide several key advantages:

- Increased Productivity: Reduces downtime associated with long charging periods.

- Enhanced Safety: Minimizes risks related to improper handling or charging.

- Optimized Workflow: Allows for strategic placement of swapping stations within warehouses.

How can battery pogo stands enhance the swapping process?

Battery pogo stands facilitate easier and safer battery swaps by providing a stable platform for lifting and positioning batteries. They streamline the process, allowing operators to quickly and efficiently exchange batteries while minimizing physical strain and reducing the risk of accidents.

| Feature | Benefit |

|---|---|

| Stability | Reduces risk of accidents during swaps |

| Accessibility | Makes it easier to reach and replace batteries |

Why is fast charging important for forklift batteries?

Fast charging is crucial as it reduces downtime, allowing forklifts to return to operation more quickly. It enables opportunity charging during short breaks, maximizing productivity and efficiency in warehouse operations. Fast charging also supports better fleet management by ensuring batteries are always ready for use.

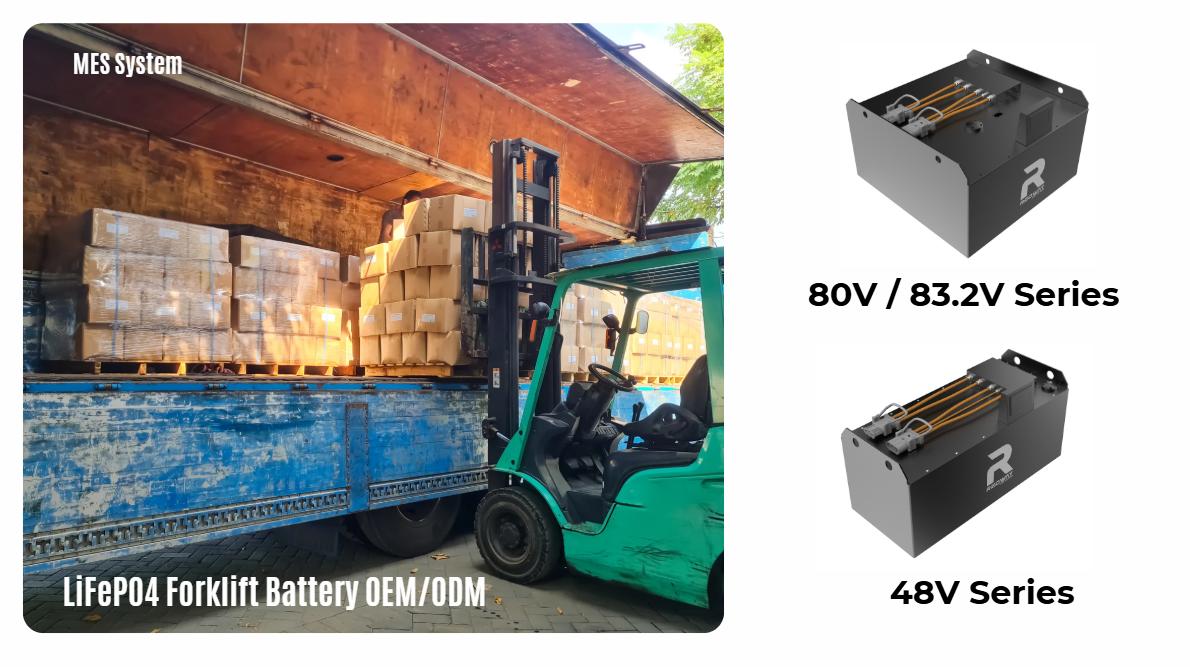

Can I buy LiFePO4 batteries for my forklift?

Yes, you can buy LiFePO4 (Lithium Iron Phosphate) batteries for your forklift. These batteries are known for their safety, long cycle life, and thermal stability, making them an excellent choice for electric forklifts in various applications.

Can I use a forklift battery for solar panel applications?

While it is possible to use a forklift battery for solar panel applications, it’s essential to ensure compatibility with the solar system’s voltage and capacity requirements. Forklift batteries are typically designed for high discharge rates, which may not align with typical solar energy storage needs.

What features should I look for in a battery swapping system?

When selecting a battery swapping system, consider:

- Speed of Operation: The time it takes to swap out a battery.

- Safety Features: Mechanisms to prevent accidents during swaps.

- Compatibility: Ensure the system works with your specific forklift models.

- Maintenance Requirements: Look for systems that require minimal upkeep.

Expert Views

“Battery swapping solutions are revolutionizing how we manage energy in forklift operations,” says Sarah Johnson, an industry expert in material handling. “By implementing efficient systems like pogo stands and fast chargers, businesses can significantly enhance productivity while ensuring safety.”

Frequently Asked Questions

- What is the average time required for a battery swap?

Typically, a complete battery swap takes about 5 minutes or less. - Are there any safety concerns with battery swapping?

Yes, proper training and equipment are essential to minimize risks associated with heavy lifting and electrical connections. - How many batteries should I have on hand for effective swapping?

Ideally, having at least two fully charged batteries per forklift ensures continuous operation without downtime. - What maintenance do LiFePO4 batteries require?

LiFePO4 batteries generally require less maintenance than lead-acid options but should be regularly checked for connections and overall condition.