Description

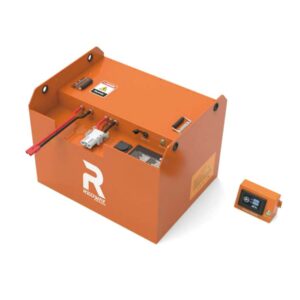

Our 48V 460Ah LiFePO4 Forklift Battery is engineered for high-performance industrial applications, combining a robust 32.2kWh energy capacity with advanced safety and durability. Designed for wholesale and OEM integration, this lithium battery delivers unmatched efficiency, long cycle life, and seamless cloud monitoring for reliable power solutions in demanding environments.

Key Features

High Energy Density: With 32.2kWh nominal energy, this LiFePO4 battery maximizes runtime for heavy-duty equipment.

Extended Cycle Life: Over 3,500 cycles at 80% depth of discharge (DOD) ensure long-term cost savings.

Enhanced Safety: Advanced BMS protects against overcurrent, overheating, and voltage fluctuations.

Dual Connectivity: RS485 and CAN-bus enable seamless integration with OEM systems.

Product Description

Built for industrial scalability, our lithium battery features a rugged metal shell, IP67-rated protection, and natural cooling for stable operation in extreme temperatures (-20¡ãC to 60¡ãC). The on-the-shell LCD display and 4G cloud monitoring provide real-time insights, while Anderson 350A and Rema 320A connectors ensure high-power reliability.

Technical Excellence

The 16S2P configuration balances power and safety, supporting 300A continuous discharge and 1,000A peak surges. As a lithium battery manufacturer, we prioritize precision engineering, offering a 51.2V system optimized for forklifts, AGVs, and renewable energy storage. Customizable communication protocols cater to diverse OEM requirements.

A 48V 630Ah LiFePO4 forklift battery offers high energy capacity, long cycle life, fast charging, and enhanced safety, making it ideal for demanding industrial material handling. Its lightweight design and advanced Battery Management System (BMS) maximize forklift efficiency and reduce operational costs.

What Are the Key Specifications of a 48V 630Ah LiFePO4 Forklift Battery?

The 48V 630Ah LiFePO4 forklift battery typically operates at a nominal voltage of 51.2V with a capacity of 630Ah, delivering approximately 32.25 kWh of energy. It weighs around 228 kg and measures roughly 950 x 592 x 450 mm, fitting various forklift models. The battery supports continuous discharge currents of up to 200A and peak discharge currents of 1000A for short bursts. It features an IP54-rated metal casing, ensuring protection against dust and moisture. The operating temperature range spans from -20°C to 60°C for discharge and 0°C to 55°C for charging. An integrated smart BMS monitors voltage, current, temperature, and state of charge to ensure safety and optimize performance.

| Specification | Detail |

|---|---|

| Nominal Voltage | 51.2V |

| Capacity | 630Ah |

| Energy | ~32.25 kWh |

| Weight | ~228 kg |

| Dimensions (L×W×H) | 950 x 592 x 450 mm |

| Continuous Discharge Current | 200A |

| Peak Discharge Current | 1000A (short bursts) |

| IP Rating | IP54 |

| Operating Temperature Range | -20°C to 60°C (discharge), 0°C to 55°C (charge) |

| Cycle Life | >3500 cycles (70% DOD) |

| Battery Management System | Integrated smart BMS |

How Does a 48V 630Ah LiFePO4 Battery Improve Forklift Performance?

This battery enhances forklift performance by delivering consistent, high-capacity power for extended shifts, reducing downtime with fast charging capabilities. Its lightweight design improves vehicle handling and efficiency, while the advanced BMS ensures optimal battery health and safety. The high peak discharge current supports demanding workloads requiring quick bursts of power, making it suitable for heavy-duty industrial operations.

What Are the Safety Features of a 48V 630Ah LiFePO4 Forklift Battery?

Safety features include:

-

Advanced Battery Management System (BMS): Monitors and controls voltage, current, temperature, and state of charge to prevent overcharging, over-discharging, overheating, and short circuits.

-

Thermally Stable Chemistry: LiFePO4 cells are inherently safer, reducing risks of thermal runaway.

-

Robust Metal Casing: IP54 protection guards against dust and moisture ingress.

-

Communication Interfaces: RS485 and CANBus enable real-time monitoring and fault detection.

-

Built-in Alarms: Alerts operators to abnormal conditions for proactive maintenance.

These measures ensure safe operation in challenging industrial environments.

How Is the 48V 630Ah LiFePO4 Battery Charged and Maintained?

Charging requires a compatible LiFePO4 charger with a recommended charging voltage of 58.4V and a maximum charge current of 200A. Fast charging reduces downtime and supports multi-shift operations. Maintenance is minimal, involving periodic terminal cleaning, avoiding deep discharges below recommended voltage, and monitoring battery health via the BMS or cloud-based systems. Proper charging and maintenance extend battery life and maintain performance.

Which Forklift Models Are Compatible with the 48V 630Ah LiFePO4 Battery?

This battery is compatible with a wide range of electric forklifts from leading brands such as Toyota, Crown, Hyster, Linde, Hyundai, and Clark. Its standard dimensions and integrated communication protocols facilitate OEM and aftermarket installation, making it a versatile choice for upgrading or replacing traditional lead-acid batteries.

What Are the Environmental Benefits of Using a 48V 630Ah LiFePO4 Forklift Battery?

LiFePO4 batteries offer significant environmental advantages:

-

Longer Lifespan: Reduces battery waste and frequency of replacements.

-

Non-toxic Materials: Lithium iron phosphate chemistry avoids harmful heavy metals.

-

Energy Efficiency: Higher charge/discharge efficiency lowers energy consumption.

-

Emission-Free Operation: No off-gassing or acid spills, improving workplace safety.

-

Recyclability: Components are more recyclable than lead-acid alternatives.

These factors contribute to greener, more sustainable warehouse operations.

How Does Heated Battery Enhance the 48V 630Ah LiFePO4 Forklift Battery?

Heated Battery incorporates specialized heating elements within their 48V 630Ah LiFePO4 batteries to maintain optimal operating temperatures in cold environments, preventing capacity loss and performance degradation. Their batteries feature intelligent BMS with remote monitoring and diagnostics, ensuring real-time insights and proactive maintenance. The rugged construction and IP54 protection make Heated Battery’s products reliable in harsh industrial conditions, supporting uninterrupted forklift operation year-round.