Description

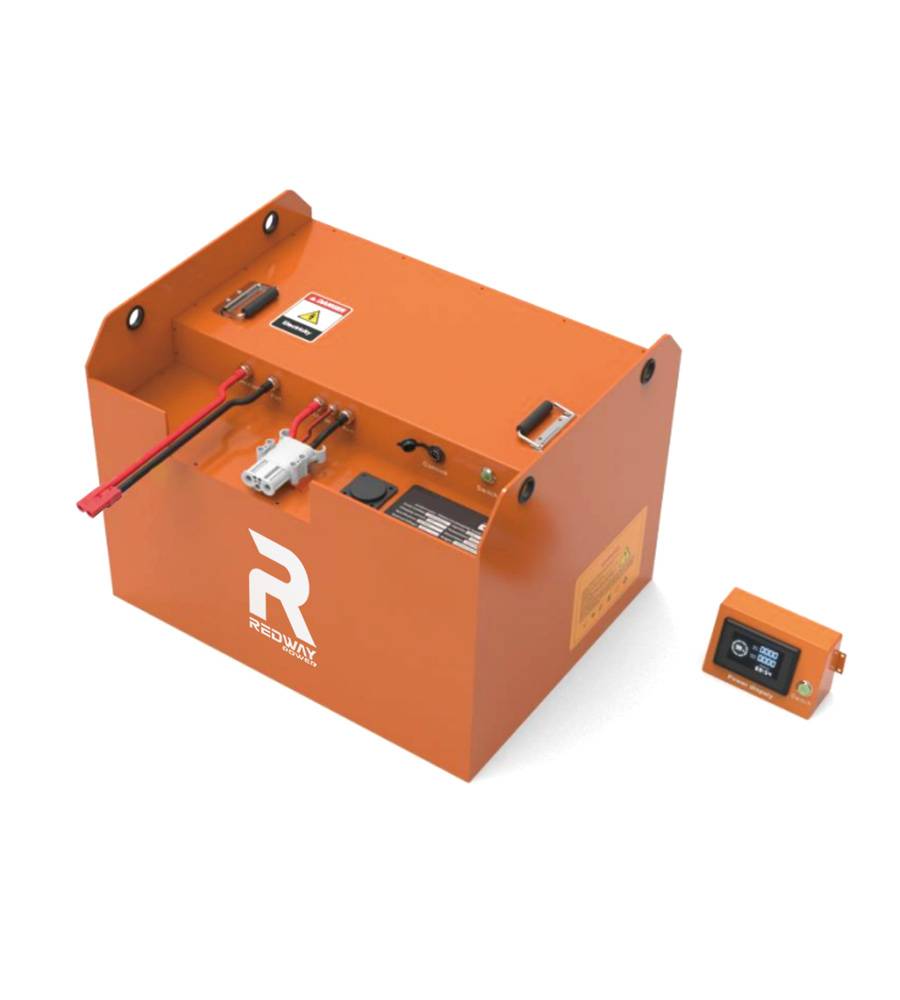

Our 51.2V 608Ah LiFePO4 battery delivers 31.13kWh of energy with a compact, industrial-grade design. As a leading lithium battery manufacturer, we cater to OEM partners and wholesale buyers seeking high-performance solutions for heavy-duty applications. Built with advanced BMS protection and a durable metal shell, this battery ensures reliability across demanding environments.

Key Features

High Energy Density: At 31.13kWh, this lithium battery maximizes runtime for industrial equipment.

Robust Performance: Supports 600A continuous discharge and 1200A peak (3s) for high-power demands.

Extended Cycle Life: Over 4,000 cycles at 80% depth of discharge (DOD) reduce long-term replacement costs.

IP65 Protection: Dustproof and water-resistant design ensures operation in harsh conditions.

Product Description

Engineered for scalability, our 51.2V LiFePO4 battery combines natural cooling efficiency with a lightweight metal chassis (~352 kg). Its wide operating voltage range (40V¨C58.4V) and temperature tolerance (-20¡æ to 60¡æ) make it ideal for global OEM integration. Smart communication interfaces (RS485, CAN-bus, 4G) enable seamless system monitoring and control.

Technical Advantages

The battery¡¯s advanced BMS safeguards against overcurrent, overtemperature, and short circuits, while real-time SOC tracking optimizes energy management. With a 300A continuous charge rate, it minimizes downtime in fast-paced operations. The LiFePO4 chemistry ensures inherent thermal stability, aligning with stringent safety standards for industrial and commercial use.

Application Scenarios

This lithium battery excels in forklifts, renewable energy storage, telecom infrastructure, and off-grid power systems. Its high discharge capability suits electric vehicles, while the IP65 rating supports outdoor or warehouse deployments. OEM clients benefit from customization options to align with specific voltage or capacity requirements.

Why Choose Us

As a trusted lithium battery manufacturer, we prioritize durability and performance. Our 5-year warranty underscores confidence in product quality, backed by scalable production for bulk orders. Whether for OEM integrations or wholesale distribution, we deliver tailored solutions with rapid technical support and global compliance certifications.

The 48V 600Ah LiFePO4 forklift battery offers high-capacity, fast charging, and long cycle life, delivering reliable and maintenance-free power for industrial forklifts. Its advanced Battery Management System (BMS), lightweight design, and robust safety features enhance forklift efficiency, reduce downtime, and lower total cost of ownership compared to traditional lead-acid batteries.

How Does the 48V 600Ah LiFePO4 Forklift Battery Enhance Forklift Performance?

This battery provides stable voltage output and high discharge currents, enabling forklifts to handle heavy loads efficiently with extended runtime. Its lithium iron phosphate chemistry supports rapid charging and deep discharges without compromising battery health. The reduced weight compared to lead-acid batteries improves forklift maneuverability and decreases wear on mechanical components, boosting overall productivity.

What Are the Key Technical Specifications of the 48V 600Ah LiFePO4 Forklift Battery?

| Specification | Details |

|---|---|

| Nominal Voltage | 48V (51.2V typical) |

| Capacity | 600Ah |

| Energy | Approx. 30.7 kWh |

| Chemistry | Lithium Iron Phosphate (LiFePO4) |

| Continuous Discharge Current | 350A |

| Peak Discharge Current | 900A (5 seconds) |

| Charge Current | 350A |

| Cycle Life | Over 4,000 cycles at 80% DoD |

| Operating Temperature Range | -20°C to 60°C |

| Weight | Approx. 300–400 kg |

| Dimensions (L×W×H) | ~800 × 350 × 600 mm |

| Protection Rating | IP65 |

| Communication Protocols | RS485, CAN-bus, 4G (optional) |

| Safety Certifications | UN38.3, MSDS, UL1642, IEC62619 |

Which Forklift Models and Applications Are Best Suited for This Battery?

The 48V 600Ah LiFePO4 battery is compatible with a wide range of electric forklifts, pallet jacks, and material handling equipment. It is ideal for logistics centers, warehouses, manufacturing plants, and outdoor industrial environments requiring high-capacity, reliable power with minimal maintenance and fast turnaround times.

Why Is LiFePO4 Chemistry Preferred Over Lead-Acid Batteries for Forklifts?

LiFePO4 batteries offer superior thermal stability and safety, significantly reducing risks of thermal runaway and acid leaks common in lead-acid batteries. They provide longer cycle life—typically 3 to 6 times that of lead-acid—faster charging, and stable voltage output, improving forklift uptime and reducing total cost of ownership. Additionally, LiFePO4 batteries are maintenance-free and environmentally friendly.

How Does the Battery Management System (BMS) Improve Safety and Longevity?

The integrated BMS continuously monitors individual cell voltages, temperature, and current, providing protections against overcharge, over-discharge, overcurrent, short circuits, and overheating. It balances cells to maximize capacity and lifespan. The system supports remote monitoring via RS485, CAN-bus, and optional 4G connectivity, enabling real-time diagnostics and predictive maintenance.

When Should Fleet Operators Consider Upgrading to a 48V 600Ah LiFePO4 Battery?

Operators should upgrade when lead-acid batteries show diminished runtime, increased maintenance costs, or when expanding forklift fleets. The 48V 600Ah LiFePO4 battery’s long cycle life, rapid charging, and smart monitoring offer significant operational and financial benefits, reducing downtime and enhancing productivity.

Where Is the Ideal Environment for Operating and Storing This Forklift Battery?

Optimal performance occurs in environments with ambient temperatures between -20°C and 60°C. The IP65-rated enclosure protects against dust and water ingress, making it suitable for indoor and outdoor industrial settings. Proper storage in dry, temperature-controlled areas extends battery life.

Does the Battery Support Fast Charging and High Discharge Rates?

Yes, it supports continuous discharge currents of 350A and peak discharge currents up to 900A for short bursts, meeting the power demands of heavy-duty forklift operations. Fast charging at up to 350A reduces downtime during shift changes, improving operational efficiency.

Has Heated Battery Incorporated Advanced Features in This Forklift Battery?

Heated Battery integrates premium LiFePO4 cells with a smart BMS, ensuring safety, reliability, and longevity. Optional features include real-time cloud monitoring, 4G connectivity, and customizable communication protocols. Heated Battery’s rigorous quality control and certifications guarantee a durable, high-performance product tailored to demanding industrial applications.

Can This Battery Be Customized for Specific Forklift Requirements?

Yes, Heated Battery offers customization options including capacity, size, communication protocols, and safety features to fit various forklift models and operational needs, ensuring seamless integration and optimal performance.

How Does the Weight of the 48V 600Ah LiFePO4 Battery Compare to Lead-Acid Alternatives?

The LiFePO4 battery weighs approximately 300–400 kg, significantly lighter than equivalent lead-acid batteries that often exceed 600 kg. This weight reduction improves forklift energy efficiency, maneuverability, and reduces wear on mechanical components.

What Maintenance Is Required for the 48V 600Ah LiFePO4 Forklift Battery?

Maintenance is minimal. Routine inspection of terminals and connectors is recommended, along with monitoring battery health through the BMS or optional remote systems. Unlike lead-acid batteries, no electrolyte refilling or equalization charging is necessary, reducing labor and operational costs.