Description

Overview

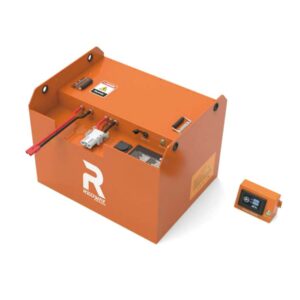

The 48V 460Ah LiFePO4 Forklift Battery is a high-performance, industrial-grade lithium battery designed for demanding applications. With 23.55kWh of energy storage, advanced BMS protection, and a rugged metal shell, this solution combines durability and efficiency. As a leading lithium battery manufacturer, we cater to OEM partners and wholesale buyers seeking reliable, scalable power systems.

Key Features

High Energy Density: Delivers 23.55kWh in a compact 830 x 630 x 590 mm footprint, ideal for space-constrained installations.

Robust Performance: Supports 400A continuous discharge and 900A peak current (3s) for heavy-duty operations.

Extended Cycle Life: Over 4,000 cycles at 80% depth of discharge (DOD), reducing long-term replacement costs.

IP65 & Natural Cooling: Dustproof, water-resistant design with passive thermal management ensures reliability in harsh environments.

Product Description

Engineered for industrial applications, the 48V 460Ah LiFePO4 Forklift Battery features a wide operating voltage range (40V¨C58.4V) and operates in temperatures from -20¡æ to 60¡æ. Its advanced BMS safeguards against overcharge, short circuits, and temperature extremes, while RS485/CAN-bus/4G connectivity enables real-time monitoring. As a lithium battery manufacturer specializing in OEM solutions, we prioritize scalability and compliance with global safety standards.

Technical Advantages

Rapid Charging: Accepts 200A continuous charge current, minimizing downtime.

Low Maintenance: LiFePO4 chemistry eliminates electrolyte refilling and acid leaks.

Lightweight Design: At ~339 kg, it reduces vehicle strain compared to traditional lead-acid alternatives.

Applications

This battery excels in forklifts, AGVs, renewable energy storage, and marine systems. Its modular architecture allows OEM partners to customize configurations for diverse voltage and capacity requirements.

Warranty & Support

Backed by a 5-year warranty, our lithium battery solutions include dedicated technical support and global logistics assistance. Partner with a manufacturer committed to innovation, quality, and long-term performance for OEM and wholesale projects.

Capacity & Performance of 48V LiFePO4 Forklift Batteries

What is the capacity of 48V LiFePO4 forklift batteries?

The capacity of 48V LiFePO4 forklift batteries typically ranges from 300Ah to 600Ah, with 460Ah being a common configuration. This capacity ensures that the forklift can operate for several hours under normal loads before requiring a recharge, making them ideal for high-demand warehouse environments. The battery’s high energy density maximizes operational time while minimizing downtime.

How does voltage affect LiFePO4 battery performance?

The voltage of a LiFePO4 battery directly impacts its power output and efficiency. A higher voltage results in increased energy transfer, making the forklift more efficient during operations. With 48V LiFePO4 batteries, forklifts can deliver consistent, high power, providing better performance than lower voltage batteries. Additionally, the higher voltage reduces the need for large battery banks, optimizing space and reducing weight.

What applications use 48V 460Ah forklift batteries?

48V 460Ah LiFePO4 forklift batteries are commonly used in electric forklifts, reach trucks, and pallet jacks for medium to heavy-duty warehouse tasks. These batteries are suitable for indoor environments with demanding operational cycles. The capacity is ideal for industries such as logistics, manufacturing, and distribution centers, providing long operational hours and efficient performance for a wide range of material handling equipment.

Are LiFePO4 batteries safer than lead-acid alternatives?

Yes, LiFePO4 batteries are generally safer than lead-acid batteries. They are thermally stable and less prone to overheating or thermal runaway, reducing the risk of fire or explosion. LiFePO4 chemistry also eliminates the hazards of acid spills and toxic gas emissions, common with lead-acid batteries. Their built-in battery management systems (BMS) further protect against overcharging, short-circuiting, and deep discharging.

What maintenance is required for LiFePO4 forklift batteries?

LiFePO4 forklift batteries require minimal maintenance. Regular checks should include monitoring State of Charge (SOC) and ensuring proper Battery Management System (BMS) function. Unlike lead-acid batteries, LiFePO4 batteries do not need watering or acid level adjustments. Proper charging practices, such as avoiding deep discharges and high-temperature exposure, help maintain their longevity and performance.

How does temperature impact LiFePO4 battery lifespan?

Temperature has a significant effect on the lifespan of LiFePO4 batteries. High temperatures can accelerate degradation, reducing battery life, while extreme cold can impair performance by slowing down chemical reactions. To maximize lifespan, it’s essential to operate and store LiFePO4 batteries in moderate temperature ranges (typically between 0°C to 45°C). Temperature-regulated environments improve efficiency and protect the battery’s health over time.

Pricing & Market Trends of LiFePO4 Forklift Batteries

What factors influence LiFePO4 battery wholesale pricing?

The wholesale pricing of LiFePO4 batteries is influenced by factors such as raw material costs, production volume, and supplier agreements. Bulk orders tend to reduce the per-unit price, while factors like battery size, BMS features, and custom specifications can also impact the cost. Supply chain disruptions, particularly for lithium and phosphate components, can further affect pricing trends.

How do LiFePO4 battery costs compare to other lithium batteries?

LiFePO4 batteries generally cost less than other types of lithium batteries like NCM (Nickel-Cobalt-Manganese). This is because LiFePO4 is made from more abundant and less expensive materials, such as iron and phosphate. While LiFePO4 has a slightly lower energy density than NCM, its safety, lifespan, and stability make it a more cost-effective choice for industrial applications like forklifts.

What are current LiFePO4 battery factory production trends?

Recent trends in LiFePO4 battery production focus on improving energy density and reducing manufacturing costs. The push for larger scale production is leading to lower unit prices as economies of scale take effect. Additionally, advancements in battery management systems (BMS) and smart charging are improving the efficiency and longevity of these batteries. Manufacturers are also increasing investment in automation and recycling capabilities.

How does supply chain affect LiFePO4 wholesale prices?

The supply chain plays a crucial role in determining the cost of LiFePO4 batteries. Fluctuations in the availability of key raw materials like lithium, iron phosphate, and graphite can result in price volatility. Additionally, shipping costs and delays in the global supply chain, especially during periods of high demand, can impact wholesale pricing. Efficient supply chains help suppliers stabilize pricing.

What regions offer competitive LiFePO4 battery wholesale rates?

Regions such as China, India, and Southeast Asia typically offer more competitive pricing due to low manufacturing costs and access to abundant raw materials. Manufacturers in Europe and North America may charge higher prices due to labor and regulatory standards, but they offer higher quality control and additional features like extended warranties and customization options.

How to negotiate better pricing with LiFePO4 battery suppliers?

To negotiate better pricing, buyers should consider ordering in bulk, ensuring a long-term supply agreement, and requesting discounts based on payment terms. Additionally, providing suppliers with forecasted demand and exploring options for customized configurations may lead to more favorable pricing. Working with suppliers who prioritize long-term relationships can also improve negotiation outcomes.

LFP Forklift Battery Performance & Benefits

What is the lifespan of LFP batteries in forklifts?

LFP (LiFePO4) forklift batteries have a lifespan of 4,000 to 6,000 cycles, which translates to about 8 to 10 years of use, depending on the operational environment and maintenance. This extended lifespan is much longer than the 1,000 cycles typical of lead-acid batteries. Proper charging and temperature management can further extend the battery’s performance.

How do LFP batteries improve forklift efficiency?

LFP batteries enhance forklift efficiency by providing consistent power throughout their discharge cycle. They charge faster than lead-acid batteries and offer higher energy density, which reduces downtime and increases overall productivity. Additionally, LFP batteries are lightweight, allowing forklifts to carry heavier loads without compromising speed or maneuverability.

What maintenance do LFP forklift batteries require?

LFP forklift batteries require minimal maintenance. Basic tasks include monitoring State of Charge (SOC), ensuring Battery Management System (BMS) functions correctly, and maintaining appropriate operating temperatures. Unlike lead-acid batteries, LFP batteries do not need to be watered or checked for acid levels. Regular inspections for damage or corrosion and proper charging habits will extend battery life.

Are LFP batteries cost-effective for industrial forklifts?

Yes, LFP batteries are cost-effective in the long term, even though their initial cost may be higher than lead-acid batteries. Their long lifespan, lower maintenance costs, and fast charging times lead to substantial savings over time, especially in high-demand environments. Moreover, LFP batteries contribute to reduced downtime, improving overall operational efficiency and profitability.

How do LFP batteries compare to lead-acid forklifts?

LFP batteries outperform lead-acid batteries in several key areas. They have a much longer lifespan, charge faster, and require less maintenance. They also offer better energy efficiency, reducing electricity costs over time. Additionally, LFP batteries are more environmentally friendly since they contain no lead or acid. However, lead-acid batteries still have a lower initial cost.

What safety features do LFP forklift batteries offer?

LFP forklift batteries have built-in Battery Management Systems (BMS) that monitor voltage, temperature, and current to prevent overcharging, deep discharging, or overheating. They are more thermally stable and safer than lead-acid batteries, reducing the risk of fire or chemical spills. Their non-toxic, non-corrosive nature further enhances workplace safety.

LiFePO4 Forklift Battery Suppliers & Installation

Top LiFePO4 suppliers for electric forklifts?

Top LiFePO4 suppliers for electric forklifts include BYD, CATL, Panasonic, and Pylontech. These suppliers provide reliable, high-quality batteries with advanced safety features, efficient performance, and long-lasting durability. They cater to a range of industrial applications, including material handling and warehouse logistics.

Compare LiFePO4 battery costs and quality?

LiFePO4 battery costs vary depending on the supplier, battery size, and custom features. However, high-quality LiFePO4 batteries from reputable brands like BYD or CATL tend to be priced higher due to superior performance, safety features, and longer lifespan. In contrast, lower-priced options may offer basic features but still provide significant cost savings over lead-acid batteries.

How to evaluate LiFePO4 battery suppliers?

When evaluating LiFePO4 battery suppliers, consider factors such as certifications, warranty terms, and customer support. The supplier should also offer customization options for your forklift model and have a proven track record in battery performance and reliability. Reviews, quality control processes, and after-sales support are also crucial evaluation metrics.

Installation requirements for LiFePO4 forklift batteries?

Installing LiFePO4 forklift batteries requires ensuring proper voltage compatibility with the forklift. A professional technician should handle the installation to ensure correct battery management system (BMS) configuration and that all safety features are in place. Some forklifts may require minimal modifications, such as adjusting battery tray sizes.

Key performance metrics for LiFePO4 batteries?

Key performance metrics for LiFePO4 batteries include cycle life, charging efficiency, energy density, and thermal stability. These batteries are designed for high cycle life (4,000–6,000 cycles), faster charge times, and optimal energy output under varying temperatures. Thermal stability and safety features also contribute to their overall performance in industrial settings.

Industry trends in LiFePO4 forklift batteries?

Current trends in LiFePO4 forklift batteries focus on improving energy density, charging speeds, and battery management systems. Suppliers are investing in sustainability, with efforts to recycle and reduce environmental impact. Additionally, there is growing demand for customized battery solutions and smart technology to optimize forklift performance and reduce operational costs.