Description

Overview

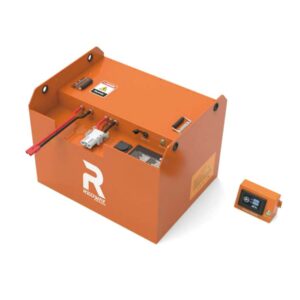

The 48V 460Ah LiFePO4 Forklift Battery is a high-performance lithium battery solution engineered for industrial applications. With a robust 23.5kWh energy capacity, advanced BMS protection, and IP67-rated durability, this battery delivers unmatched reliability for OEM partners and wholesale buyers seeking long-term, cost-effective power solutions.

Key Features

High Energy Density: At 23.5kWh, this lithium battery provides extended runtime for demanding equipment like forklifts.

Peak Performance: Supports 300A continuous discharge and 1000A peak current (5s) for high-power applications.

Durable Design: Metal shell, natural cooling, and IP67 rating ensure resilience in harsh environments.

Smart Monitoring: Cloud-based 4G connectivity and an LCD screen enable real-time tracking of SOC, temperature, and system health.

Scalable Configuration: 16S2P cell architecture allows seamless integration into custom OEM systems.

Product Description

Designed for industrial OEMs and wholesale buyers, the 48V 460Ah LiFePO4 Forklift Battery combines 51.2V nominal voltage with a compact footprint (950¡Á421¡Á450 mm). Its LiFePO4 chemistry ensures >3,500 cycles at 80% DOD, reducing replacement costs. The dual communication ports (RS485/CAN-bus) simplify fleet management, while Anderson 350A and Rema 320A connectors guarantee secure power transfer.

Safety and Reliability

The integrated BMS safeguards against overcharge, overdischarge, and temperature extremes (-20¡ãC to 60¡ãC). With certifications for short-circuit prevention and multi-layer fault detection, this lithium battery prioritizes operational safety for mission-critical environments.

Technical Specifications

Weighing ~190 kg, the battery operates efficiently across a 40V¨C58.4V range. Its 0¡ãC¨C55¡ãC charging tolerance and natural cooling system minimize downtime, while the 5-year/3,500-cycle warranty underscores its longevity.

Warranty and Support

Backed by a 5-year warranty, this manufacturer-certified product includes lifetime technical support. OEM clients benefit from scalable customization options, including tailored communication protocols and form factors.

Why Choose Us?

As a trusted lithium battery manufacturer, we specialize in high-capacity solutions for OEM and wholesale markets. Our 48V 460Ah LiFePO4 Forklift Battery exemplifies innovation in energy storage, delivering industrial-grade power with minimal maintenance and maximum ROI.

Voltage and Capacity of LiFePO4 Forklift Batteries

What is the voltage and capacity of LiFePO4 forklift batteries?

LiFePO4 forklift batteries typically have a nominal voltage of 48V, with capacities ranging from 200Ah to 600Ah or more. For example, a 48V 460Ah battery offers a high-energy capacity suitable for heavy-duty operations in industrial settings. This combination of voltage and capacity ensures that the forklift can operate for extended hours with minimal downtime, providing excellent performance in demanding environments. The capacity is measured in amp-hours (Ah) and determines the battery’s energy storage.

How long do 48V 460Ah LiFePO4 batteries typically last?

A 48V 460Ah LiFePO4 battery can last between 4,000 to 6,000 charge cycles, significantly outlasting traditional lead-acid batteries. Depending on usage, these batteries can last 8 to 10 years or more, especially when well-maintained. The lifespan of LiFePO4 batteries is influenced by factors such as charging habits, temperature, and how deeply the battery is discharged. Their longevity makes them a cost-effective solution in the long run for industrial forklifts.

What are the advantages of LiFePO4 in electric forklifts?

LiFePO4 batteries offer several advantages in electric forklifts, including longer lifespan, faster charging, and greater safety. They are more energy-efficient than lead-acid batteries and require significantly less maintenance. With a lightweight design, they enhance forklift efficiency and allow for faster acceleration. LiFePO4 batteries are also safer, with thermal stability that prevents the risk of thermal runaway, making them ideal for heavy-duty forklift operations in warehouses and manufacturing facilities.

What maintenance is required for LiFePO4 forklift batteries?

LiFePO4 forklift batteries require minimal maintenance. Regular checks should be performed on the Battery Management System (BMS) to monitor voltage levels, temperature, and charge cycles. Ensure the terminals are clean and corrosion-free to maintain good electrical contact. The battery should be charged properly and never allowed to discharge below 20% to extend its lifespan. Additionally, store the battery in a cool, dry place when not in use.

How does temperature affect LiFePO4 battery performance?

Temperature can affect LiFePO4 battery performance significantly. High temperatures can lead to faster degradation and reduced cycle life, while cold temperatures can temporarily decrease efficiency and runtime. The optimal operating range is 0°C to 45°C, as temperatures outside this range can cause slower charging, reduced performance, or even battery damage. Proper temperature management is critical for maximizing the lifetime and efficiency of LiFePO4 batteries.

Are LiFePO4 batteries compatible with all forklift models?

LiFePO4 batteries are generally compatible with most forklift models, but compatibility depends on the voltage and size requirements of the specific forklift. Most modern forklifts are designed to work with lithium-ion batteries, but it is important to verify that the battery voltage and capacity match the forklift’s needs. Additionally, forklift models must have the necessary charging equipment and battery management systems (BMS) to accommodate the unique characteristics of LiFePO4 batteries.

LiFePO4 Battery Pricing, Market Trends & Benefits

What factors influence LiFePO4 battery wholesale pricing?

LiFePO4 battery wholesale pricing is influenced by factors such as raw material costs, battery capacity, and production scale. Supply chain disruptions, labor costs, and manufacturing location also impact prices. Additionally, demand for sustainable solutions in industrial equipment and increased adoption of electric vehicles contribute to rising prices. The level of battery customization and certifications required can also affect the cost.

How do LiFePO4 batteries benefit industrial machinery?

LiFePO4 batteries benefit industrial machinery by providing higher energy density, faster charging, and longer lifespan compared to traditional batteries. They offer consistent performance throughout the charge cycle, reducing downtime. These batteries require minimal maintenance, leading to lower operational costs. LiFePO4 technology is also more eco-friendly, making it a popular choice for industries looking to reduce their carbon footprint while improving productivity in material handling and other machinery applications.

What are current LiFePO4 battery market trends?

The LiFePO4 battery market is seeing increasing demand due to its cost-effectiveness and environmental benefits. Trends include greater adoption of LiFePO4 batteries in electric vehicles, forklifts, and renewable energy storage systems. Innovations in battery technology are leading to improvements in charging speed, energy density, and cycle life. There is also a shift toward factory-direct sales and automation in manufacturing processes to reduce costs and increase supply chain efficiency.

How to compare LiFePO4 with other lithium batteries?

LiFePO4 batteries differ from other lithium chemistries like NCM and NCA in terms of energy density, safety, and cost. LiFePO4 batteries are known for greater thermal stability, safer operation, and a longer cycle life, but they typically have lower energy density than other lithium-ion types. LiFePO4 is more cost-effective and eco-friendly, making it ideal for industrial applications like forklifts, while NCM and NCA offer higher energy density for more compact applications.

What strategies reduce LiFePO4 procurement costs?

To reduce LiFePO4 procurement costs, consider bulk purchasing from reliable suppliers, which offers discounted prices. Partnering with local manufacturers and direct sourcing from factories can also lower import taxes and shipping fees. Ensuring accurate battery specifications to avoid overbuying or underbuying capacity is essential. Leveraging long-term contracts and evaluating suppliers based on quality and warranty can also help reduce overall costs.

How does supply chain affect LiFePO4 battery prices?

Supply chain factors such as raw material availability, transportation costs, and production capacity significantly impact LiFePO4 battery prices. Disruptions in the supply of key materials like lithium, phosphate, and iron can lead to price volatility. Global demand for electric vehicles and renewable energy storage further influences the market. Efficient supply chains help mitigate price hikes and reduce the cost per unit for large-scale purchases.

LiFePO4 Battery Features, Safety & Cost Efficiency

What is LiFePO4 battery energy density?

LiFePO4 batteries have a lower energy density compared to other lithium-ion chemistries like NCM or NCA, typically around 90-120 Wh/kg. However, this is offset by their longer lifespan, thermal stability, and safety advantages. While they store less energy per kilogram, LiFePO4 batteries are ideal for applications where safety and cost are more critical than maximum energy density, such as forklifts and material handling equipment.

How does LiFePO4 cycle life compare?

LiFePO4 batteries have an exceptional cycle life, often reaching up to 4,000 to 6,000 cycles, significantly outlasting lead-acid batteries. This means that LiFePO4 batteries can endure many more charge and discharge cycles before their capacity starts to degrade, providing long-term reliability in industrial applications. The longer cycle life reduces the frequency of replacements, making them a cost-effective choice for businesses with high power demands.

Charging time for high-capacity LiFePO4?

The charging time for a high-capacity LiFePO4 battery, such as a 48V 460Ah model, is typically 4 to 6 hours using a fast charger. LiFePO4 batteries charge faster compared to traditional lead-acid batteries, which can take up to 8-12 hours. Fast charging is a key benefit in industrial operations where minimized downtime is essential, allowing forklifts and equipment to be quickly ready for use after each shift.

Temperature effects on LiFePO4 performance?

LiFePO4 batteries perform best in moderate temperature conditions (0°C to 45°C). Extreme cold can slow down the charge/discharge cycles, while high heat can cause faster degradation of the battery cells. At high temperatures, LiFePO4 batteries may experience capacity loss or potential safety issues. Maintaining optimal operating temperature conditions ensures maximum efficiency and longer lifespan. Thermal management is essential for battery performance, especially in hot climates or industrial environments.

LiFePO4 safety features in forklifts?

LiFePO4 batteries are known for their superior safety due to thermal stability and resistance to thermal runaway. Unlike other lithium-ion batteries, they do not catch fire easily when overcharged or exposed to high temperatures. Most LiFePO4 batteries also feature Battery Management Systems (BMS) that monitor voltage, current, and temperature, ensuring safe operation. These systems help prevent overcharging, overdischarging, and other dangerous conditions, making them ideal for use in forklifts.

Cost-efficiency of LiFePO4 vs lead-acid?

LiFePO4 batteries offer superior cost-efficiency over time compared to lead-acid batteries. Although the upfront cost of LiFePO4 is higher, its long lifespan (4-6 times longer than lead-acid) and minimal maintenance needs result in lower overall ownership costs. LiFePO4 batteries also charge faster, reducing downtime, and do not require costly watering or acid maintenance. In the long run, LiFePO4 batteries are more economical for businesses focused on reducing operational costs.

LiFePO4 Battery Maintenance and Lifespan

What are LiFePO4 battery advantages for forklifts?

LiFePO4 batteries offer longer cycle life, faster charging, and safer operation for forklifts. These batteries are lightweight, requiring less maintenance than lead-acid alternatives, and provide consistent performance over longer durations. LiFePO4 batteries also have thermal stability, reducing risks in high-heat environments. Their efficiency reduces downtime, making them ideal for high-demand applications like material handling. They also contribute to **lower

operational costs** and improved environmental sustainability.

How do factory-direct LiFePO4 batteries ensure quality?

Factory-direct LiFePO4 batteries ensure consistent quality by eliminating middlemen in the supply chain. Manufacturers oversee every stage of production, ensuring that the battery meets industry standards for safety, performance, and durability. Direct purchasing also allows for customized solutions to meet specific requirements. Factory-direct options can offer better pricing due to reduced costs associated with distribution, and they often come with extended warranties and direct customer support.

Can LiFePO4 batteries be customized for specific forklifts?

Yes, LiFePO4 batteries can be customized to meet the unique voltage and capacity requirements of specific forklift models. Customization can include adjusting the battery size, charging protocols, or battery management systems (BMS) to suit the specific operational needs of the forklift. Custom solutions allow businesses to get the optimal performance from their equipment, improving efficiency and operational safety.

Are LiFePO4 batteries cost-effective compared to alternatives?

While LiFePO4 batteries may have a higher initial cost than lead-acid batteries, they are more cost-effective over time. LiFePO4 batteries have a longer lifespan, requiring fewer replacements. They also have lower maintenance costs, as they do not require regular watering or equalization charges. The faster charging times and greater energy efficiency reduce downtime, making them a cost-effective investment for businesses looking to improve operational productivity.

Do LiFePO4 batteries meet environmental regulations?

LiFePO4 batteries are considered eco-friendly compared to other types of batteries like lead-acid. They contain no toxic heavy metals such as lead or cadmium, making them safer for disposal and recycling. Additionally, LiFePO4 batteries are highly recyclable, reducing environmental impact. Their long lifespan also contributes to less waste over time. LiFePO4 batteries help businesses comply with environmental regulations by offering a sustainable alternative to conventional energy storage solutions.

What maintenance do LiFePO4 forklift batteries require?

LiFePO4 forklift batteries require minimal maintenance, but regular monitoring of the Battery Management System (BMS) is recommended. Ensure that the battery is kept clean and free from corrosion, and that the terminals are tightly connected. Avoid discharging the battery below 20%, and charge it fully after each use. Keep the battery in a cool, dry place and inspect it for any damage periodically. Following these simple steps can help extend the battery’s lifespan.